Copper Forging

Copper forgings are a process to obtain forging products with certain mechanical properties, certain shape and size by applying pressure to brass billet by forging machinery and making it produce plastic deformation. Forging is one of the two components of forging and stamping. By forging, the defects such as loose in the casting state produced in the smelting process of brass can be eliminated, and the microstructure of brass can be optimized. At the same time, the mechanical properties of forged brass are generally better than the castings of the same material because the complete brass streamline is preserved.

The company produces and sells copper forgings, etc,welcome to buy.

Email: [email protected]

WhatsApp: 0086-18301953841

| Grade list of copper and copper alloys by country | |||||||

| Classification | China | Germany | America | Japan | England | Europe | International |

| oxygen free copper | TU1 | 2.0076 | C10200 | C1020R | C103 | ||

| TU2 | Cu-OF-H110 | C11000 | c1011 | C101 | |||

| Vacuum oxygen free copper | E-Cu58 | TU00 | c1020 | 6N | |||

| high purity | copper-OFE | c10500 | c10700 | ||||

| Silver copper | TAg 0.1 | CuAg 0.1 | C10400 | C1040 | CuAg 0.1 | ||

| brass | H90 | CuZn10 | C22000 | C2200 | CZ101 | CuZn10 | CW501L |

| H70 | CuZn30 | C26000 | C2600 | CZ106 | CuZn30 | CW505L | |

| H68 | C26200 | C2620 | CuZn33 | CW506L | |||

| H65 | CuZn35 | C27000 | C2700 | CZ107 | CuZn36 | CW507L | |

| H63 | CuZn37 | C27200 | C2720 | CZ108 | CuZn37 | CW508L | |

| H62 | CuZn40 | C28000 | C2800 | CZ109 | CW509L | ||

| bronze | QSn4-0.3 | CuSn4 | C51100 | C5111 | PB101 | CuSn4 | CW450K |

| CuSn5 | C51000 | C5101 | CuSn5 | CW451K | |||

| QSn6.5-0.1 | CuSn6 | C51900 | C5191 | PB103 | CuSn6 | CW452K | |

| QSn8-0.3 | CuSn8 | C52100 | C5210 | CuSn8 | CW453K | ||

| QSn6.5-0.4 | |||||||

| copper-nickel | BZn18-18 | CuNi18Zn20 | C75200 | C7521 | NS106 | CuNi18Zn20 | |

| BZn18-26 | CuNi18Zn27 | C77000 | C7701 | NS107 | CuNi18Zn27 | CW410J | |

| BZn15-20 | C7541 | CW409J | |||||

| BZn18-10 | C7350 | ||||||

| pure copper | TU2 | OF-Cu58 | C10100 | C1011 | C101 | CW008A | copper oxide |

| T2 | SW——copper | C11000 | C1100 | C101 | copper - FRHC | ||

| TP2 | SF-Cu | C12200 | C1220 | C106 | CW024A | copper - DHP | |

| TP1 | SW-copper | C12000 | C1201 | CW023A | copper DLP | ||

Red Copper

As a copper material with high content, red copper has better stability, corrosion resistance and oxidation resistance, and excellent electrical conductivity compared with brass, bronze, zinc and copper. It is one of the ideal materials for copper bar profiles.

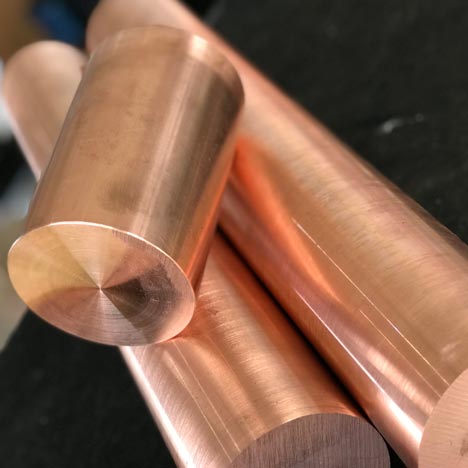

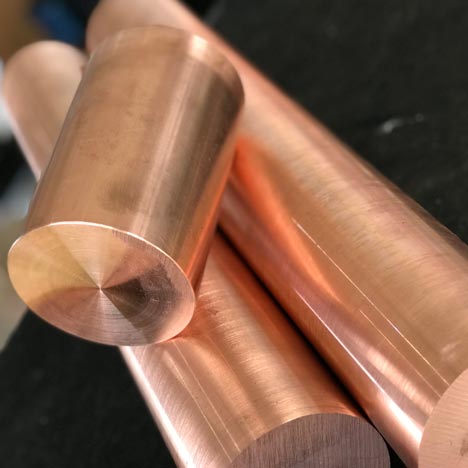

Copper Electrode

Good plasticity, machining forming, forging forming, electroforming forming and wire cutting forming, fine texture, good processing stability, relatively small electrode loss, wide adaptability.

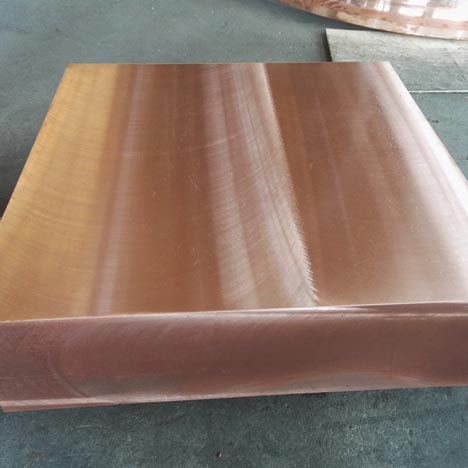

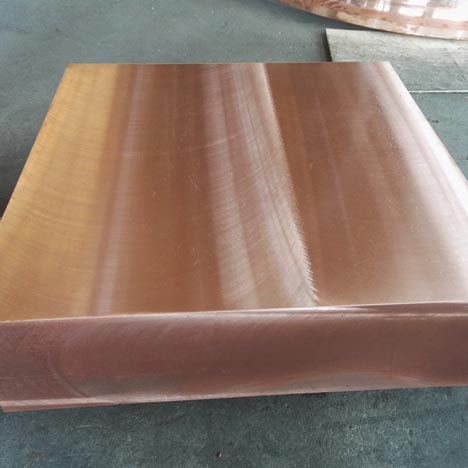

Mould Copper

The main material of die copper waste is copper, which is a metal material of alloy. The ductility of alloy copper used in die casting die is low, the linear expansion coefficient is small, and the mold made of it is stable in performance and specification. Mold cavity selection of investment casting, aluminum die casting or hot forging and other forming process, short manufacturing cycle, low cost. Used in die casting moulds.

1. Wide range of weight. Forgings range from a few grams to hundreds of tons.

2. Higher quality than castings. The mechanical properties of forgings are better than those of castings, which can withstand large impact force and other heavy loads. Therefore, some important parts with large forces are used for forgings.

3. The lightest. On the premise of ensuring the design strength, the weight of the forgings is lighter than that of the castings, which reduces the weight of the machine itself, which is of great significance to the vehicles, aircraft, vehicles and airborne lifting equipment.

4. Save materials. For example, when the crankshaft with a static weight of 17kg is used in the car, the chip takes up 189% of the weight of the crankshaft when the rolling cutting forging is adopted, while the chip takes up only 30% when the die forging is adopted, and the machining time is shortened by 1/6.

5. High productivity. For example, 30 automatic cutting machines can be replaced by two hot die forging press die forging radial thrust bearings. The productivity of 6-axis automatic lathe is 17.5 times of M24 nut production by using push forging automaton.

6. Free forging is flexible, so it is widely used in some repair factories to produce various accessories.

We also provide CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.