Ti 13V 11Cr 3Al

Titanium 13TV-11Cr-3Al Bar is a beta alloy deformed titanium alloy that undergoes solution treatment before aging. It has good ductility and processability, and when aged produces extremely high strength and low density. This alloy is known for its excellent corrosion resistance.

Specifications:

AMS 4917, AMS 4959, AMS 6926, MIL-F-83142, MIL-T-9046, MIL-T-9047, UNS R58010

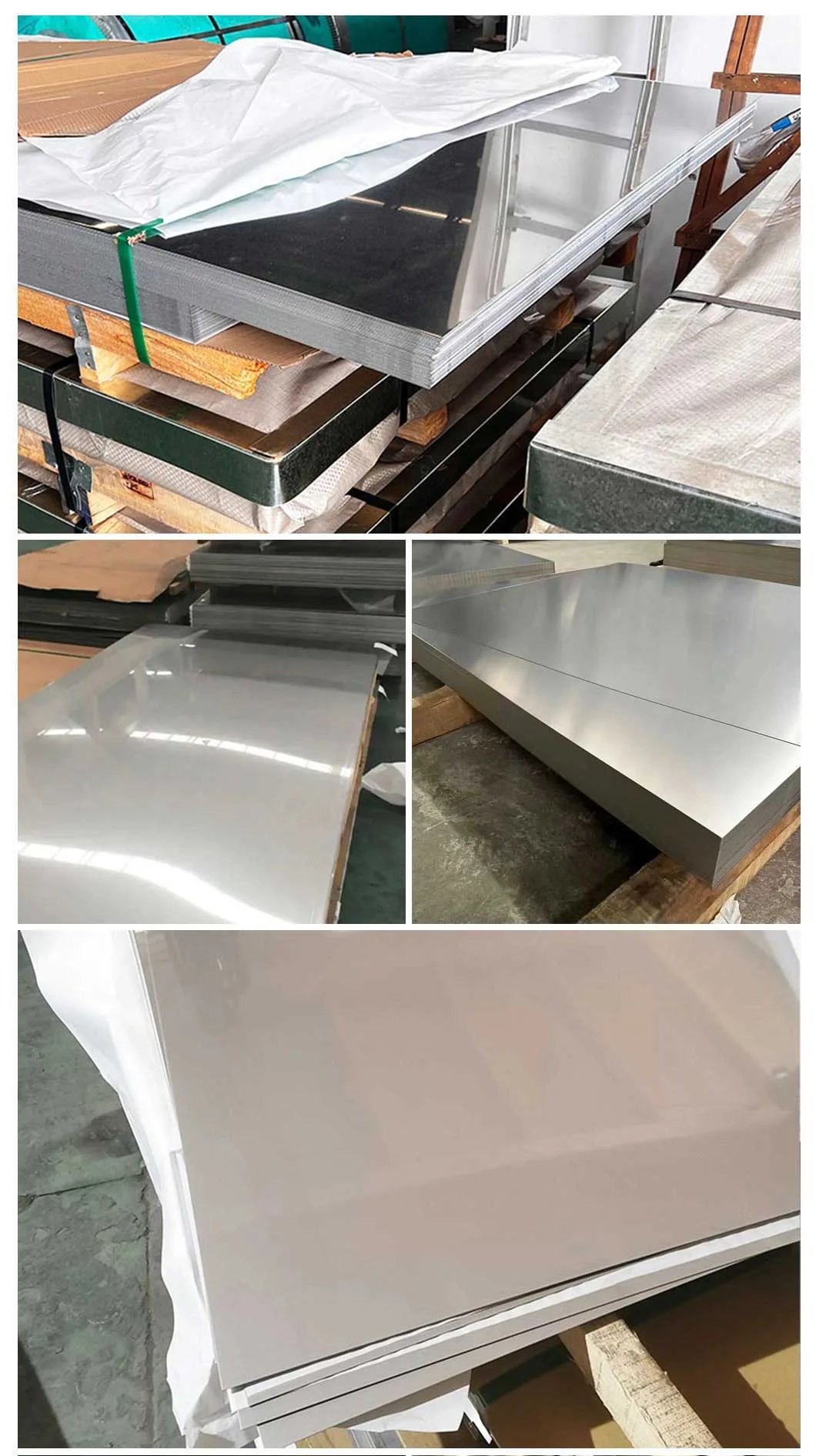

Product size can be customized according to customer needs.

Applications:

High strength airframe components, Areospace and missile applications, springs.

We can provide customized services of different sizes according to customer needs. In addition, our company also produces titanium alloy materials in various shapes, such as: wire, sheet,tube, strip, and plate, bars, forgings, and stock for forging.

Email: [email protected]

WhatsApp: 0086-18301953841

Chemical Composition

The chemical composition of grade Ti-13V-11Cr-3Al alloy is outlined in the following table.

| Element | Content (%) |

|---|---|

| Vanadium, V | 12.5 - 14.5 |

| Chromium, Cr | 10-12 |

| Aluminum, Al | 2.5 - 3.5 |

| Iron, Fe | 0.35 max |

| Oxygen, O | 0.17 max |

| Carbon, C | 0.05 max |

| Nitrogen, N | 0.05 max |

| Hydrogen, H | 0.025 max |

| Titanium, Ti | Remainder |

Physical Properties

| Properties | Metric | Imperial |

|---|---|---|

| Density | 4.84 g/cm3 | 0.175 lb/in3 |

Mechanical Properties

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength | 1276 MPa | 185068 psi |

| Yield strength | 1207 MPa | 175060 psi |

| Poisson's ratio | 0.304 | 0.304 |

| Elastic modulus | 101.4 GPa | 14706 ksi |

| Elongation at break | 8% | 8% |

| Hardness (HRC) | 40 | 40 |

Thermal Properties

| Properties | Conditions | ||

|---|---|---|---|

| T (°C) | Treatment | ||

| Thermal expansion | 9.4 x 10-6/°C | 20-100 | - |

Machinability

Grade Ti-13V-11Cr-3Al alloy is hard to machine but can be successfully done using slow speeds, high coolant flow, and high feed rates. Tooling should be performed using tungsten carbide designations C1-C4 or cobalt type high speed tools.

Forming

Grade Ti-13V-11Cr-3Al alloy can be hot or cold formed.

Welding

Welding of grade Ti-13V-11Cr-3Al alloy is rated as good.

Annealing

Full annealing of this material can be performed by heating to 788°C (1450°F) for 15 min and then air cooled.

Forging

Forging can be performed at 1065-1176°C (1950-2150°F).

Hot Working

Hot working enhances the overall ductility of the material.

Cold Working

Cold working features of this material is same as that of a moderately tempered austenitic stainless steel. Post-work annealing is recommended to re-attain favorable performance properties.

We also provide CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.